Transitioning from diesel to electric truck fleets presents unique challenges, especially in developing a robust charging infrastructure. This guide outlines six critical steps to ensure fleet managers can effectively design and implement an electric fuel solution tailored to their operational needs.

Step 1: Analyzing Fleet Requirements

The journey begins with a thorough analysis of your fleet’s real-world applications. This involves more than just counting the number of electric vehicles (EVs); it requires a deep dive into each vehicle’s duty cycles and available charging windows. This comprehensive analysis will determine the specific types and quantities of chargers needed, and whether your trucks will charge sequentially or simultaneously.

Step 2: Engaging Early with Utilities

The U.S. Department of Energy emphasizes the importance of involving local utilities early in your fleet’s electrification journey. With increased electricity demands, especially for simultaneous high-rate charging, understanding the impact on your power grid is crucial. Remember, establishing a charging infrastructure is a lengthy process, potentially taking up to two years or more. Early engagement with utilities is key to avoiding charging roadblocks upon delivery of your EVs.

Step 3: Collaborating with Stakeholders

Electrifying your fleet is not a solo endeavor. Collaboration with a range of stakeholders — including landlords, building code enforcers, OEMs, charger manufacturers, architects, and contractors — is essential. This team effort ensures a smooth and efficient build-out of your EV charging infrastructure, addressing potential issues like permitting and easements early in the process.

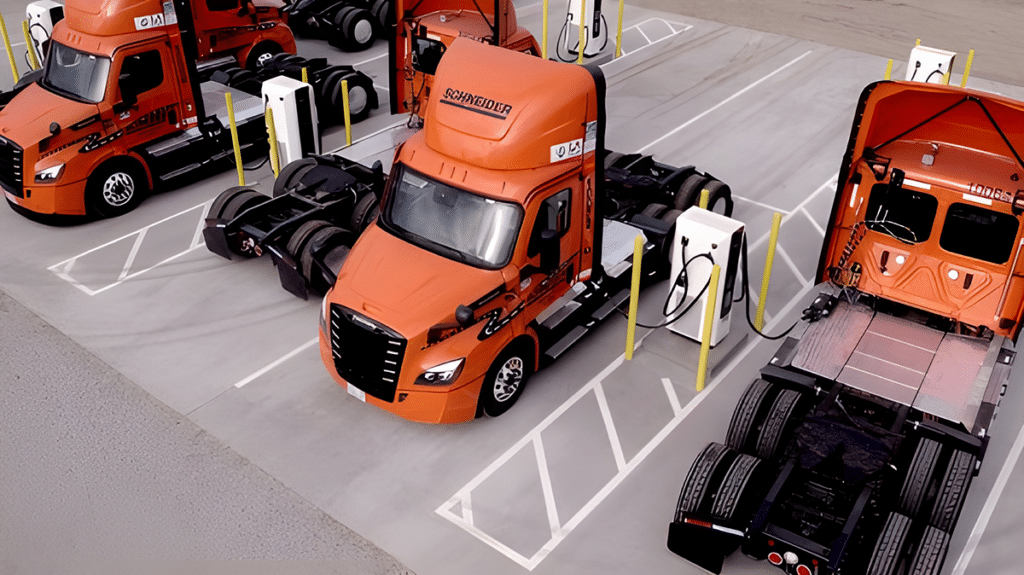

Step 4: Designing and Building Charging Infrastructure

This critical phase starts with assessing your site’s existing electrical capacity and usage. Understanding your baseline is vital for creating an optimal charging solution. Considerations like charger placement, particularly for medium- and heavy-duty trucks, are central to your infrastructure design. Pull-through charging stations, for instance, offer considerable advantages. Additionally, exploring grants and incentives through resources like the DOE’s Alternative Fuels Data Center can significantly offset costs.

Step 5: Monitoring and Adapting Charging Practices

Choosing the right EV charging solution is just the beginning. Continuous monitoring is necessary to minimize charging costs and accommodate fleet expansions or changes in duty cycles. This might involve adjusting charging times or sequences to ensure operational and cost efficiency.

Step 6: Seeking Expert Assistance

If the prospect of electrifying your fleet seems daunting, support is available. Electrada’s 360 Charging-as-a-Service (360 CaaS) offers comprehensive assistance, managing every aspect from start to finish while absorbing all capital costs. With a focus on tailored solutions, Electrada ensures your transition to electric fueling is smooth and customized to your specific needs.

Electrifying your fleet is a complex but manageable journey. By following these six steps and seeking expert guidance when needed, you can confidently navigate the transition to a sustainable, efficient electric fleet fuel solution. For personalized assistance, and to learn more about how 360 CaaS might serve as your EV fleet’s complete electric fuel solution, get in touch with Electrada.