As the electric vehicle (EV) market surges forward, it brings into sharp focus the potential strain on utility distribution grids. Utilities, well-versed in adapting to new demands, now face the intricate challenge of harmonizing burgeoning customer charging needs with the existing infrastructure. There exists a delicate balancing act that emphasizes the critical need for clear communication and precise planning between customers and utilities.

Electrada, leveraging decades of industry expertise that its team bring, is acutely aware of the localized impacts that EV depots can have on utilities. The Electrada team engages in a holistic collaborative process, aligning vehicle allocations with depot locations, and crafting meticulous capacity plans that are both robust for the present and adaptable for the future. These plans, alongside detailed operating load shapes, are shared proactively with local utilities, ensuring they have the necessary data to make informed decisions regarding infrastructure upgrades.

Electrada’s 360 Charging-as-a-Service (360 CaaS) offers a comprehensive EV fleet charging solution, encompassing everything from site assessment to full capitalization of charging systems and related energy assets. The Electrada team, applying rigorous analysis and innovative design, ensures the creation of a secure, resilient, and performance-backed EV charging infrastructure, ready for both current and future demands. Once implemented, Electrada takes charge of the operation and maintenance of the EV charging equipment, all underpinned by a robust Service Level Agreement (SLA), creating a balanced and efficient “mobility microgrid” for a seamless multi-year service relationship.

Electrada Mobility Microgrid Solution Architecture

Electrada’s sophisticated microgrid architecture proactively and dynamically adjusts site loads to fulfill the electrical demands of each individual charger, all while adeptly managing grid electricity supply. This ensures the maximization of utility Time-of-Use (TOU) rate advantages. Additionally, the system seamlessly integrates available on-site solar energy and dispatchable Battery Energy Storage Systems (BESS) when present. This integration not only guarantees consistent power quality but also ensures that electricity is delivered to each charger—and consequently, to each vehicle—at the most economical cost per kWh, drawing from a diverse range of energy sources. Electrada deftly navigates its energy portfolio, employing a combination of retail utility energy, wholesale power agreements, on-site BESS, and even specific utility demand response (DR) programs when opted for by the customer, all in the pursuit of optimal energy efficiency and cost-effectiveness.

The visual representation in Figure 1 highlights Electrada’s sophisticated mobility microgrid solution architecture, a critical tool employed for the daily management of fleet depot operations. Engaged in active management, Electrada skillfully balances energy requirements, aligning them with the predetermined load shape designated for each charging session. To ensure precision and efficiency across every site, Electrada seamlessly integrates a suite of solutions including an Energy Management System (EMS), BESS controls, a Charger Management System (CMS), and a Fleet Management System (FMS). This integration facilitates the receipt and processing of fleet telematics, enabling the development and refinement of charger management schedules. The ultimate goal is to achieve the performance and uptime benchmarks set forth in the Service Level Agreements (SLAs) for each individual site, ensuring a harmonious and efficient operation.

The Significance of Load Shape in Charging Sites

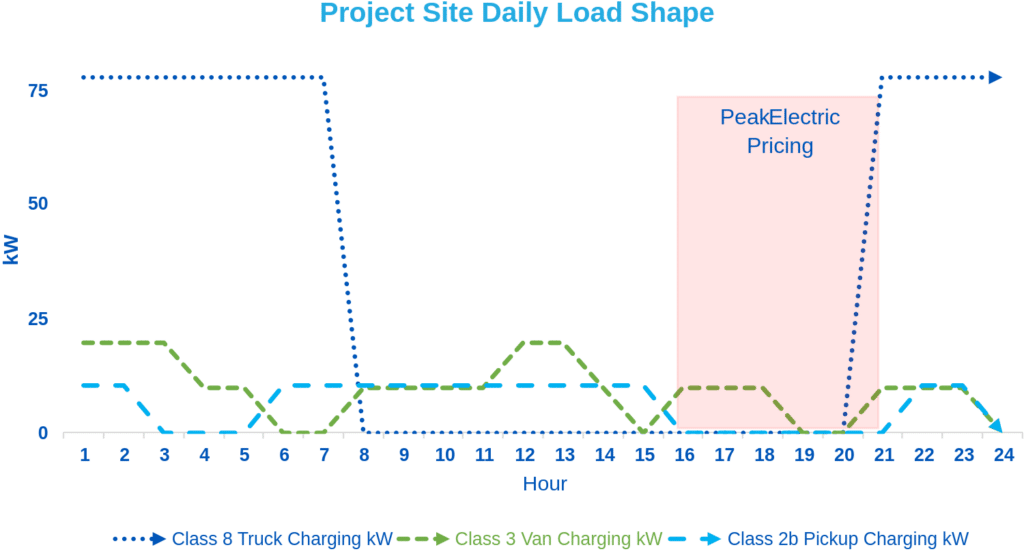

The seamless operation of Electrada’s charging solution, as previously outlined, hinges on its ability to generate and consistently refine the load shape at the customer’s site, translating to a detailed hourly energy demand across the entire year. This load shape encapsulates the total anticipated electrical demand for charging at a particular site, synthesizing data from the Fleet Management System (FMS), as well as accounting for the vehicles’ daily operational patterns, cargo loads, and preconditioning needs.

Electrada leverages this comprehensive load shape to meticulously plan electrical capacity, incorporating elements such as sensitivity analysis and provisions for redundancy and reliability. This ensures the formulation of a robust and resilient energy plan. The initial load shape, which includes allowances for potential fluctuations, plays a pivotal role in the planning phase. However, Electrada’s approach is dynamic, employing updated load shapes to capture real-world variations in EV performance, meteorological conditions, cargo weights, and site-specific constraints. This adaptability ensures service continuity and operational efficiency throughout the engagement term, whether it necessitates augmenting Battery Energy Storage Systems (BESS) or fine-tuning the energy supply in response to shifts in vehicle performance.

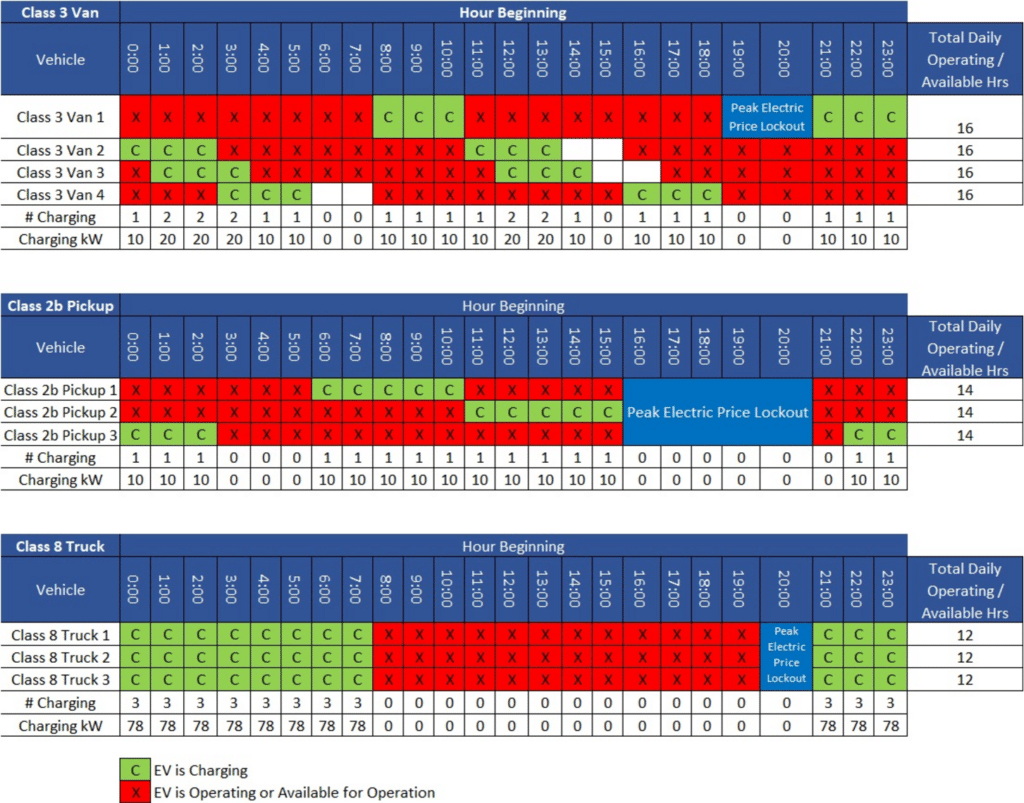

Illustrative Case: Depot Site Load Shape

In the critical stages of project design and solution development, Electrada engages in comprehensive collaborations with its customers, delving deep to understand the daily operational plans for their vehicle fleets. This involves a meticulous analysis of the technical specifications of the vehicles, ensuring a thorough verification of both charging capacities and battery sizes. The rate at which an electric vehicle (EV) charges directly influences the instantaneous energy demand, measured in kilowatts (kW), while the size of the EV’s battery dictates the duration required for a full charge, measured in kilowatt-hours (kWh). Electrada skillfully synthesizes these parameters to craft a daily energy load shape, serving dual purposes: as a tool for internal operations and cost management, and as invaluable data provided to utilities for grid planning.

This energy load shape is pivotal, forming the bedrock for critical decisions such as determining the appropriate quantity and capacity of charging stations required, as well as ascertaining the overall energy expenditure for charging the fleet. These elements are integral, feeding into the formulation of a fixed pricing strategy for the duration of the project. Consequently, this structure inherently incentivizes Electrada to adhere to the established load shapes, ensuring optimal depot operation and cost efficiency.

Leveraging its advanced CMS and EMS systems, Electrada meticulously optimizes both site load limits and charging schedules, ensuring energy utilization aligns seamlessly with planned parameters, while maintaining transparency with utilities through active participation in demand response programs. In scenarios where collaboration with utilities unveils potential short-term capacity or grid challenges, Electrada proactively integrates on-site BESS systems, enhancing capacity during peak periods, aiding utility operations, and fostering energy cost savings.

Harnessing a sophisticated architecture, Electrada deftly manages site loads, optimizing electric supply and integrating renewables to ensure efficient power delivery at minimal costs. Electrada navigates energy portfolios and utility programs, translating real-time data into actionable energy capacity plans. This proactive approach guarantees adaptability to variables like EV range and weather, ensuring operational excellence and cost-effectiveness throughout the service term.

In Summary

As the energy landscape evolves, necessitating further generation capacity and grid enhancements, Electrada stands as a pivotal partner for utilities. By owning and operating customer depots via its 360 CaaS solution, Electrada not only supplies utilities with comprehensive annual hourly load shapes for strategic planning but also ensures steadfast adherence to these load shapes, guaranteeing operational excellence throughout the depot’s lifecycle. To learn more about how Electrada can help streamline your fleet electrification efforts, please get in touch.