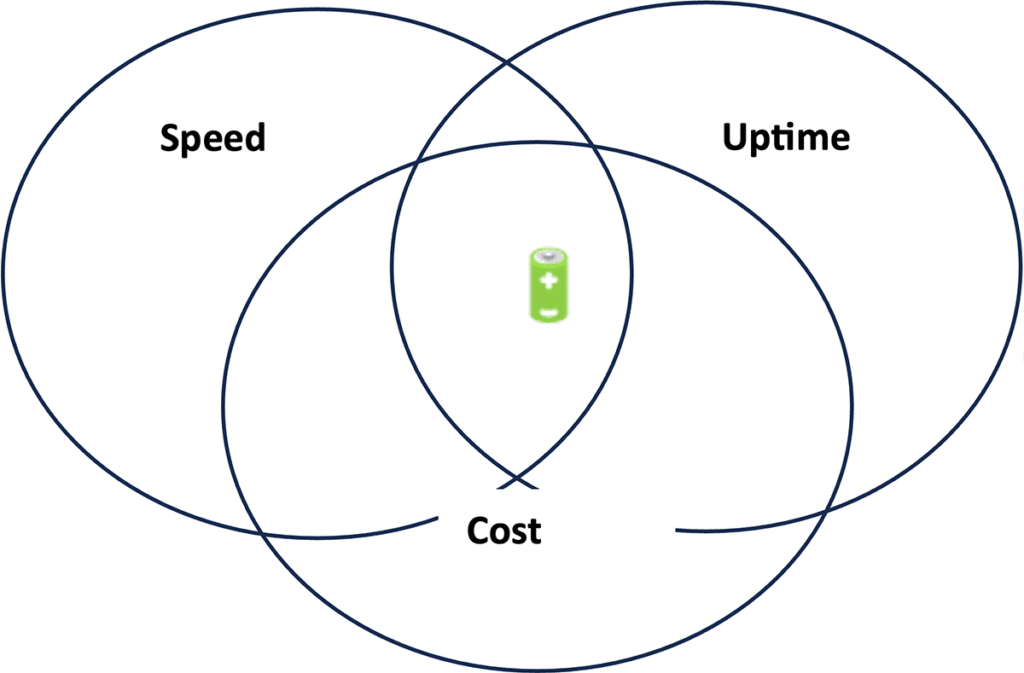

Is it possible to balance the critical aspects of speed, uptime, and cost in electric vehicle (EV) fleet charging? Achieving this ‘Goldilocks zone’ is not only possible but essential for successful fleet electrification and sustainable mobility.

Speed: Making Every Second Count

Speed in fleet charging isn’t just about how fast the batteries get charged; it’s about keeping EVs on the road longer and reducing downtime. A major Key Performance Indicator (KPI) in fleet electrification is the EV utilization rate. The faster the charging, the higher the utilization. To understand this, consider the State of Charge (SOC): it’s calculated by dividing the EV battery capacity (kWh) by the charge point speed (kWh). This seems technical, but it’s vital for maximizing efficiency.

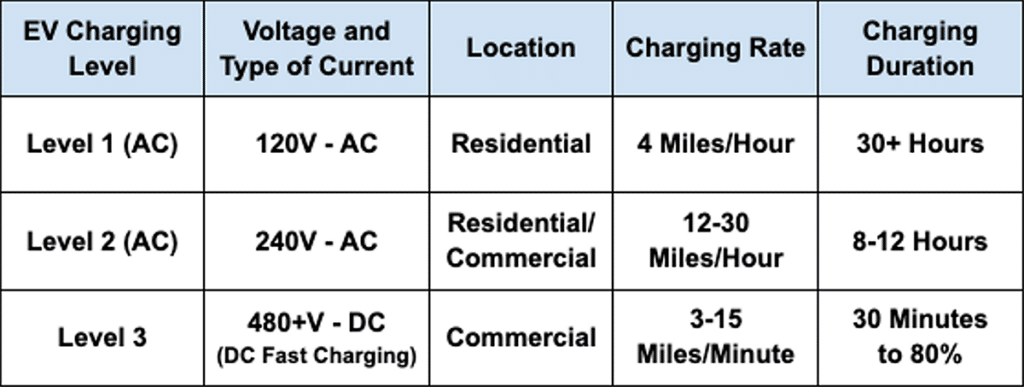

Factors like the EV’s on-board charger capacity and the power output of the Electric Vehicle Supply Equipment (EVSE) play a significant role here. Don’t forget external factors like ambient temperature. Below is a simplified chart showing average charging rates across different scenarios:

Uptime: Keeping the Wheels Turning

Uptime is a critical fleet electrification KPI. It ensures customer satisfaction and demonstrates that sustainable fleets are both operational and cost-effective. Consider these three charging options:

- Unmanaged Charging: Suitable for some consumer vehicles but not for fleets where cost and time optimization are crucial.

- Smart Charging: This allows for remote control of charging and can include load management to monitor demand charges and site capacity.

- Managed Charging: The most advanced option, managed charging integrates EVSE with building and utility systems for optimized charging based on various factors like electrical load and cost.

These options highlight the importance of choosing the right charging strategy for your fleet’s specific needs.

Cost: Balancing the Budget

How do we achieve the desired speed and uptime without overspending? The total cost of ownership (TCO) can be reduced by transitioning from ICE vehicles to EVs, but monitoring the charging costs of these EVs is crucial. The main cost variables include EVSE hardware and software, and power consumption.

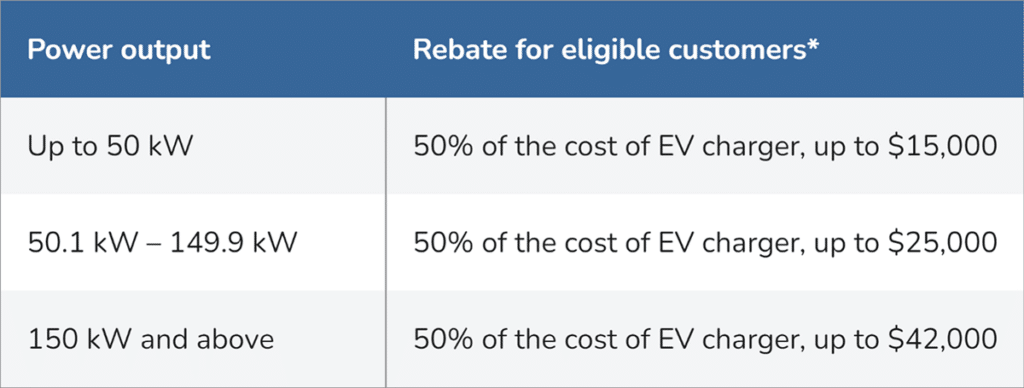

States like California and many utilities offer rebates on EVSE purchases, reducing initial costs. However, infrastructure installation and utility upgrade costs can vary widely. To manage these expenses, consider strategies like charging during off-peak hours or staggering vehicle charging to smooth out electricity demand.

Speed and uptime can be achieved – but at what cost? While measurable TCO reductions can be realized by switching from Internal Combustion Engine (ICE to) EVs, charging those EVs needs to be monitored closely. The two main variables of charging include EVSE hardware and software, and power consumption costs. Many states, notably California as well as many utilities provide rebates on the initial purchase price of eligible EVSE:

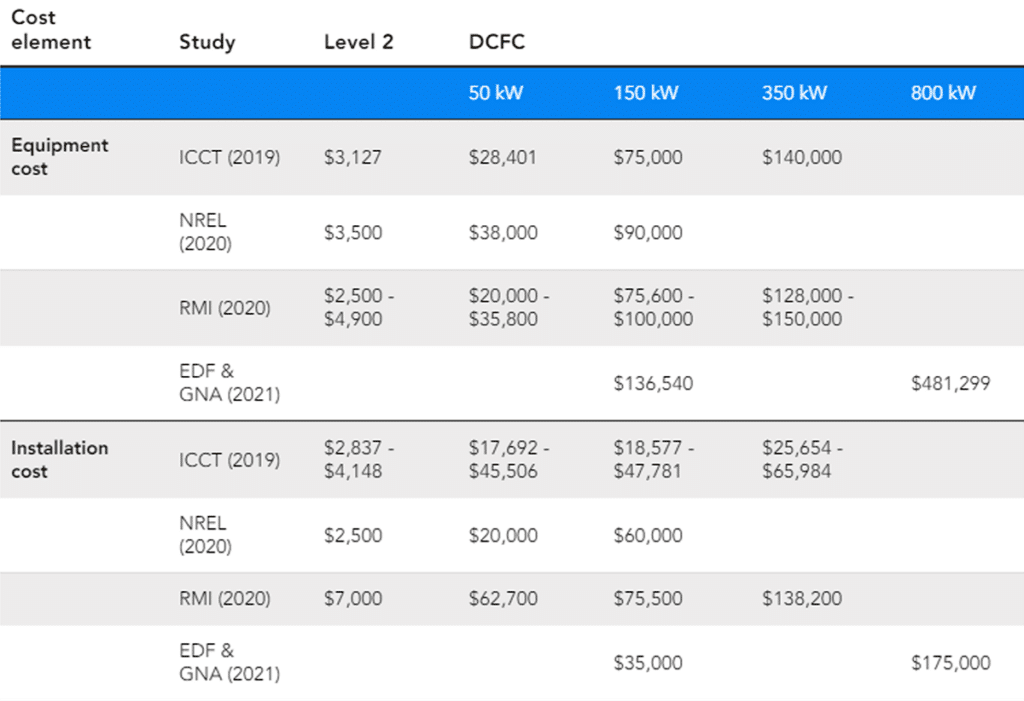

According to ICF, EV infrastructure installation and utility upgrade costs can vary significantly from $2,700 to $24,000 for L2, and $70,000 to $130,000 for DCFC:

Conclusion: Striking the Perfect Balance

To help optimize charging, RMI suggests effectively managing EV charging by “planning to charge during off-peak hours to take advantage of lower electricity rates and staggering vehicle charging to smooth out electricity demand and avoid demand charges.”

While fleet electrification is complex, the Goldilocks region of speed, uptime and cost (depicted by the battery icon in the first image above) is achievable. By strategically aligning EV adoption and charging infrastructure, as well as evaluating EV charging infrastructure, fleet operators can navigate this landscape more effectively.

Many fleets are turning to Charging as a Service (CaaS) to mitigate cost, risk, and downtime. CaaS providers like Electrada offer tailored solutions that harmonize EV charging demands with utility infrastructure, maximize available rebates, and ensure 99% uptime, a critical fleet operation KPI. The journey to efficient fleet electrification is ongoing.

By understanding and optimizing these key factors, fleet operators can make informed decisions that benefit both their operations and the environment. Get in touch with Electrada to learn more.